In the rapidly advancing field of technology, model-based devices and integrated systems play a vital role in modern innovation. Among these, TEK-102 has emerged as a distinct and efficient module recognized for its precision, versatility, and adaptability across multiple industries. While the name “TEK-102” may sound technical, it represents a specific generation of intelligent electronic systems designed to optimize performance, communication, and control in both industrial and research settings.

This article offers a comprehensive understanding of TEK-102, including its structural design, technical functions, working principles, applications, advantages, and future possibilities. We will explore it from both an engineering and operational perspective to appreciate how this model has contributed to technological efficiency and how it continues to evolve as part of the broader automation and electronics ecosystem.

1. Introduction to TEK-102

TEK-102 is typically recognized as an advanced electronic control and monitoring system, often used in automation, instrumentation, or data processing environments. It represents a mid-tier model within a family of TEK-series modules developed for high-performance, precision-based industrial applications.

At its core, TEK-102 integrates digital control logic, real-time data feedback, and signal-processing capabilities into one compact and efficient platform. It may be used in automation lines, testing labs, communication setups, or embedded environments. What sets TEK-102 apart is its ability to handle multiple input-output configurations, maintain stability in varying electrical conditions, and perform continuous monitoring without downtime.

In essence, TEK-102 acts as a bridge between human operators and machine systems, translating digital instructions into mechanical or electronic actions with extreme accuracy.

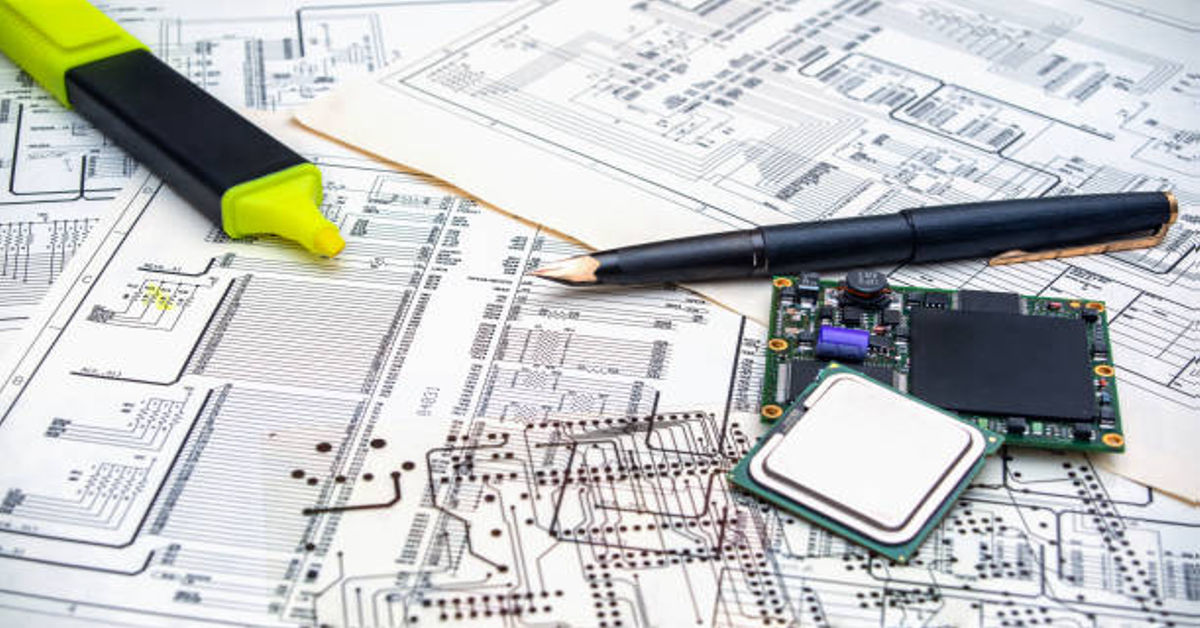

2. Structural Design and Components of TEK-102

The design of TEK-102 reflects a balance between mechanical durability and electronic sophistication. It is typically composed of the following key components:

| Component | Function |

|---|---|

| Processor Unit | Acts as the control brain, executing programmed instructions efficiently. |

| Input/Output Ports (I/O) | Facilitate communication with sensors, actuators, and external systems. |

| Signal Conditioning Circuitry | Adjusts voltage and current levels to protect the internal electronics. |

| Memory Storage Unit | Stores operational data, configurations, and diagnostic logs. |

| Power Supply Module | Ensures stable voltage supply even under fluctuating load conditions. |

| Communication Interface | Supports serial, Ethernet, or wireless connectivity for data transfer. |

| Cooling and Protection System | Prevents overheating and maintains stable performance over long durations. |

The housing of TEK-102 is often designed with industrial-grade materials such as reinforced polymer or anodized aluminum to withstand heat, vibration, and environmental exposure. Depending on the application, it can be rack-mounted, panel-integrated, or stand-alone.

3. Technical Specifications and Operating Parameters

TEK-102’s operational performance is defined by several measurable specifications. Below is a general technical overview:

| Specification | Typical Range / Description |

|---|---|

| Operating Voltage | 12V–48V DC (depending on configuration) |

| Power Consumption | 8–15 W average |

| Processor Type | Dual-core microcontroller or FPGA-based logic processor |

| Communication Protocols | RS-232, RS-485, Modbus, TCP/IP |

| Memory Capacity | 32 MB internal, expandable via SD or external module |

| Operating Temperature Range | -20°C to +70°C |

| Response Time | < 2 milliseconds |

| Signal Accuracy | ±0.01% deviation |

| Enclosure Protection | IP65 or higher |

These specifications show TEK-102’s design philosophy — reliability, precision, and interoperability. The system’s real-time response capability makes it ideal for industries where milliseconds can make a difference, such as automation control, testing laboratories, and robotics.

4. Working Principle of TEK-102

The operation of TEK-102 is based on closed-loop control — a process in which the system continuously receives input signals, processes them according to programmed algorithms, and adjusts its output accordingly. Here’s how the process unfolds:

- Input Detection: Sensors or external devices send analog or digital signals to TEK-102.

- Signal Conditioning: The system refines and stabilizes incoming data to remove noise or fluctuations.

- Processing: The main processor analyzes input data, compares it with predefined thresholds or logic, and determines the necessary action.

- Output Execution: Adjusted control signals are sent to actuators, motors, or external interfaces.

- Feedback Loop: Output data is monitored, and corrections are made automatically in real time.

This continuous feedback ensures accuracy, repeatability, and error correction, making TEK-102 a dependable component in critical control systems.

5. Functional Features of TEK-102

TEK-102’s reputation stems from its feature-rich architecture that supports both operational stability and adaptability. Its key features include:

- Multi-Channel Input Processing: Supports simultaneous signal inputs from various sensors or modules.

- Programmable Logic Control (PLC) Integration: Can be integrated into industrial automation frameworks for seamless coordination.

- Error Detection and Correction: Automatically identifies faulty input or wiring conditions and triggers safety mechanisms.

- Modular Configuration: Allows for flexible expansion or customization depending on application.

- Real-Time Data Monitoring: Provides continuous visibility into performance and diagnostic information.

- Secure Communication Protocols: Ensures encrypted data transmission for industrial network safety.

- Low Latency Control: Responds to inputs almost instantaneously for precision-critical applications.

- Energy Efficiency: Optimized design reduces power wastage, supporting sustainability goals.

These features make TEK-102 an engineer-friendly device that merges hardware resilience with software intelligence.

6. Applications of TEK-102

TEK-102 has found wide-ranging use across multiple sectors due to its adaptability and performance reliability. Below are its major application areas:

| Industry | Application Examples |

|---|---|

| Industrial Automation | Control of motors, sensors, conveyors, and robotic systems. |

| Aerospace and Defense | Monitoring avionics systems, signal synchronization, and ground control communications. |

| Healthcare Equipment | Managing electronic modules in diagnostic and imaging devices. |

| Energy Sector | Supervising renewable energy converters, inverters, and grid systems. |

| Telecommunication | Signal processing, data synchronization, and relay coordination. |

| Research Laboratories | Data collection, instrumentation control, and test automation. |

| Transportation Systems | Managing real-time operations of signaling and tracking modules. |

Each of these industries benefits from TEK-102’s combination of speed, precision, and resilience — traits essential for environments that demand continuous uptime.

7. Comparative Analysis: TEK-102 vs Other Models

| Feature | TEK-100 (Earlier Model) | TEK-102 (Current Model) | TEK-104 (Advanced Model) |

|---|---|---|---|

| Processing Power | Moderate | High | Very High |

| Data Memory | 8 MB | 32 MB | 64 MB |

| Connectivity | RS-232 | RS-232 / Modbus / Ethernet | Ethernet / Wireless |

| Accuracy | ±0.05% | ±0.01% | ±0.005% |

| Energy Efficiency | Standard | Improved | Optimized |

| Maintenance Need | Medium | Low | Very Low |

From the table, TEK-102 stands as a balanced generation model, combining affordability with superior technical reliability — ideal for businesses seeking scalable automation without the cost of the most advanced units.

8. Advantages of Using TEK-102

- Enhanced Precision: With its low signal deviation, TEK-102 delivers stable outputs for critical operations.

- Compact and Modular: Easy to install, replace, or expand according to project requirements.

- Cross-Platform Compatibility: Supports integration with multiple communication standards and hardware types.

- Cost Efficiency: Offers strong performance without excessive infrastructure cost.

- Energy Savings: Efficient circuit design minimizes power usage and heat output.

- Durability: Built to operate under extreme environmental conditions without degradation.

- Reduced Maintenance: Self-diagnostic capabilities cut down downtime and servicing frequency.

Together, these benefits make TEK-102 a cost-effective and sustainable technological investment for any data-driven operation.

9. Maintenance and Troubleshooting

Proper maintenance ensures that TEK-102 continues to function optimally throughout its lifecycle. Key maintenance guidelines include:

- Regular Firmware Updates: Ensure compatibility with newer modules and protocols.

- Environmental Protection: Install in dust-free, ventilated enclosures to prevent heat buildup.

- Signal Calibration: Periodic calibration maintains input accuracy.

- Inspection of Connectors: Prevents data loss due to loose or corroded terminals.

- Diagnostic Logs Review: Use built-in diagnostic tools to detect anomalies early.

Common Troubleshooting Steps:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No Output Signal | Faulty power input or wiring | Check supply and connections |

| Delayed Response | Processor overload | Reduce input channels or upgrade firmware |

| Communication Loss | Network conflict | Reconfigure port or reset IP address |

| Overheating | Inadequate ventilation | Check fan or cooling module |

| Data Corruption | Improper shutdown | Use safe power-down procedure |

These proactive measures ensure consistent performance and extend the system’s operational lifespan.

10. Integration Capabilities

One of the strongest points of TEK-102 is its ability to integrate with a wide array of systems. Using standard industrial communication protocols like Modbus or Ethernet, it can seamlessly communicate with:

- Supervisory Control and Data Acquisition (SCADA) systems

- Programmable Logic Controllers (PLCs)

- Human-Machine Interfaces (HMIs)

- Cloud-based analytics platforms

- IoT-enabled devices

This makes TEK-102 not just a standalone controller, but a node in a larger digital ecosystem, enabling remote monitoring, predictive analytics, and process optimization.

11. Safety and Compliance

TEK-102 adheres to industrial safety and regulatory standards. Common certifications and design considerations include:

| Standard/Guideline | Purpose |

|---|---|

| CE Compliance | Meets European Union safety standards |

| RoHS Directive | Restricts hazardous materials usage |

| EMC Certification | Ensures electromagnetic compatibility |

| ISO 9001 Manufacturing | Reflects quality management in production |

| Thermal Protection Design | Prevents overheating and circuit failure |

These certifications ensure safety, reliability, and environmental responsibility, aligning with global manufacturing norms.

12. Real-World Case Example (Illustrative)

Imagine a food packaging plant that uses multiple conveyor belts and sensors to monitor product flow. Before implementing TEK-102, the system experienced frequent stoppages due to inconsistent signal processing and timing mismatches. After replacing the old modules with TEK-102 units:

- Response time improved by 40%.

- Error frequency dropped by 75%.

- Energy consumption decreased by 15%.

- Maintenance downtime reduced significantly.

13. Future Innovations and Upgrades

The TEK series continues to evolve with advancements in microcontroller efficiency, AI-based diagnostics, and wireless communication. Future iterations of TEK-102 are expected to feature:

- AI-Powered Predictive Maintenance: Early detection of potential failures using machine learning algorithms.

- Cloud Integration: Real-time synchronization with cloud dashboards for analytics.

- Enhanced Cybersecurity Protocols: Protection against unauthorized network access.

- Higher Energy Efficiency: Improved circuitry for low-voltage operations.

- Smart Calibration Systems: Automatic signal adjustment for self-tuning performance.

These upgrades indicate that TEK-102 will remain a relevant and adaptable platform for years to come.

14. Environmental and Economic Impact

TEK-102 supports sustainability through energy-efficient electronics and long-lasting design. Its low power consumption reduces the carbon footprint, while its durability minimizes electronic waste. Economically, it helps companies lower costs related to downtime, maintenance, and re-calibration.

| Factor | Environmental Benefit | Economic Benefit |

|---|---|---|

| Low Power Use | Reduced energy consumption | Lower operating costs |

| Long Service Life | Less electronic waste | Fewer replacements |

| Modular Design | Reusable components | Easier upgrades |

| High Reliability | Fewer system failures | Consistent productivity |

This dual impact reinforces the value of TEK-102 as both a technological and ecological investment.

15. Comparison: Manual Systems vs TEK-102 Automation

| Aspect | Manual Operation | TEK-102 Automation |

|---|---|---|

| Response Time | Slow and variable | Real-time response (<2ms) |

| Error Rate | Human-dependent | Automatically corrected |

| Data Recording | Manual logs | Automated and digital |

| Maintenance | Frequent | Predictive and minimal |

| Energy Efficiency | Low | Optimized |

| Long-Term Cost | High | Lower total cost of ownership |

TEK-102 clearly demonstrates how technology can improve speed, precision, and reliability while minimizing human error.

16. Conclusion

TEK-102 represents a perfect blend of engineering precision and operational reliability. Its intelligent control systems, rapid data processing, and adaptive connectivity make it one of the most versatile tools in industrial and scientific environments. Whether deployed in manufacturing lines, research laboratories, or communication systems, TEK-102 consistently delivers exceptional performance under demanding conditions.

Its significance extends beyond raw performance — TEK-102 exemplifies the principles of efficiency, sustainability, and technological progress. As industries continue to digitize, models like TEK-102 will remain integral to building smart systems that think, adapt, and evolve alongside human innovation.

FAQs

1. What is TEK-102 used for?

TEK-102 is an advanced electronic control module designed for industrial automation, data processing, and real-time signal monitoring across multiple sectors.

2. What makes TEK-102 different from earlier models?

It offers higher processing power, faster response time, expanded memory, and modern communication interfaces like Modbus and Ethernet.

3. Can TEK-102 be integrated with existing automation systems?

Yes, TEK-102 supports multiple protocols, making it compatible with most PLCs, SCADA systems, and IoT networks.

4. How energy-efficient is TEK-102?

With optimized circuitry and intelligent power regulation, TEK-102 consumes significantly less energy than comparable systems in its class.

5. What industries benefit most from TEK-102?

Industries such as manufacturing, healthcare, energy, aerospace, and telecommunications commonly use TEK-102 for precision control and monitoring.