A sublimation printer is one of the most innovative and reliable devices used in modern printing industries, especially for printing on products such as textiles, mugs, plates, phone cases, keychains, photo panels, and various coated surfaces. Unlike traditional printers that use inkjet or laser technology, sublimation printers work on a chemical process that transforms solid dye into gas under heat and pressure without passing through a liquid stage. This unique transformation process leads to stunning, long-lasting, and highly detailed prints that do not crack, peel, or fade easily. Sublimation printing has gained immense popularity among small business owners, hobbyists, designers, and large-scale manufacturers because it provides versatility, high-resolution output, and exceptional durability. Understanding sublimation printers involves diving deeper into their mechanism, components, print media compatibility, operational workflow, advantages, limitations, maintenance requirements, and the applications that make them such a significant part of today’s printing landscape.

A sublimation printer operates using sublimation dye, which is specially formulated to work with heat transfer. The sublimation dye is transferred onto sublimation paper, and under high heat, the solid particles vaporize and embed themselves into polyester fibers or polymer-coated items. This embedding process creates permanent prints that become part of the material’s surface rather than sitting on top of it. This is why sublimation prints are extremely durable, water-resistant, and capable of maintaining their vibrancy for years. To better understand how these printers function, it is essential to explore the science behind sublimation printing, the components that make up a sublimation system, and the factors that determine print quality.

Understanding the Science Behind Sublimation Printing

Sublimation printing is based on the scientific principle of phase transition, where a solid turns directly into a gas without becoming a liquid. This transformation occurs when sublimation dyes are exposed to specific levels of heat—typically between 350°F to 400°F—and pressure. When heated, the dye molecules become active and permeate the surface of polyester fabrics or polymer-coated objects. As the material cools down, the dye molecules solidify, forming a permanent bond.

This process ensures that the printed image becomes part of the material’s structure rather than remaining on its surface. As a result, sublimation prints do not fade easily even after multiple washes, do not crack over time, and maintain consistent color vibrancy. The chemical interaction between heat-sensitive dye and polyester coating is the foundation of sublimation technology.

To bring this process to life, a sublimation printer must include specialized components and operate with precision. These printers often use MicroPiezo technology or advanced printheads that ensure the smooth and controlled release of sublimation dye. The accuracy of droplet placement, heat management, and color configuration determines the final print’s quality.

Components of a Sublimation Printer and Sublimation Setup

A complete sublimation system includes more than just a printer. Several interconnected components work together to create high-quality sublimation prints. Understanding these components is crucial for anyone intending to use sublimation technology effectively.

Table 1: Components of a Sublimation Printing System

| Component | Description | Function |

|---|---|---|

| Sublimation Printer | Specialized or converted inkjet printer | Prints sublimation designs onto transfer paper |

| Sublimation Ink | Dye-based ink that turns into gas under heat | Transfers permanent color onto coated materials |

| Sublimation Paper | Transfer paper designed for sublimation ink | Holds dye before heat application |

| Heat Press Machine | Flat, mug, or plate press depending on application | Applies heat and pressure to transfer dye |

| Software/RIP Program | Design tools for color correction and layout | Ensures accurate color output |

| Blanks | Polyester fabrics or polymer-coated items | Final products for sublimation printing |

Each component works together in a streamlined workflow. The sublimation printer first prints the design onto sublimation paper using sublimation ink. After printing, the sublimation paper is placed onto the blank item and inserted into a heat press machine. Under heat and pressure, the dye transfers into the blank, creating the final product.

Types of Sublimation Printers

Sublimation printers come in various types based on print width, ink configuration, and intended usage. Understanding the categories helps users choose the right printer for their needs.

1. Desktop Sublimation Printers

These are compact printers ideal for beginners, home users, or small businesses. Desktop models usually range between 8.5 inches to 13 inches in print width. They are commonly used for small items like mugs, coasters, and T-shirts.

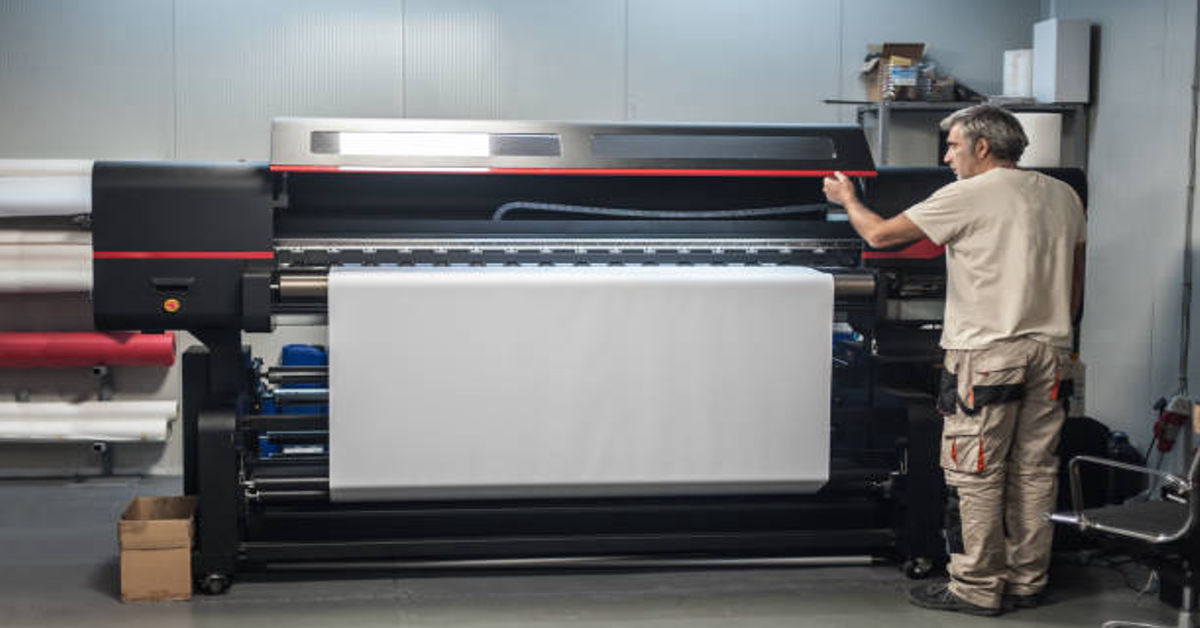

2. Professional Wide-Format Sublimation Printers

These printers handle medium to large-scale projects with print widths between 24 inches and 64 inches. They are suitable for printing large rolls of fabric, banners, textile apparel, and promotional material.

3. Industrial Sublimation Printers

Designed for mass production, these printers provide ultra-high-speed output with multiple printheads and large ink tanks. Industrial sublimation printers are typically used in textile factories and large print houses.

How Sublimation Printers Work: Step-by-Step Process

To fully understand sublimation printers, it is essential to break down their operational workflow.

1. Designing the Artwork

Users create a digital design using software such as Adobe Illustrator, Photoshop, or specialized sublimation design tools. Color profiles are essential in maintaining accuracy between on-screen colors and printed results.

2. Printing the Design

The sublimation printer prints the mirrored appearance of the design onto sublimation paper using sublimation inks. The paper holds the solid dye in place until heat is applied.

3. Preparing the Blank Item

The blank item must be polyester-based or coated with a sublimation-friendly polymer. This ensures dye absorption during heating.

4. Heat Press Transfer

The printed sublimation paper is securely taped onto the item and placed inside a heat press. Temperature, pressure, and time vary depending on the material.

5. Cooling and Final Output

After the heat press cycle finishes, the item is removed and allowed to cool. The dye cools and solidifies within the material, forming a permanent print.

Materials Compatible with Sublimation Printing

Sublimation printing is versatile but not universally compatible with all materials. Only certain materials can accept sublimation dyes.

Table 2: Compatible and Non-Compatible Materials

| Material Type | Compatibility | Notes |

|---|---|---|

| Polyester Fabric | ✔ Compatible | Best results with at least 65–100% polyester |

| Polymer-Coated Items | ✔ Compatible | Includes mugs, tiles, metal plates |

| Cotton | ✘ Not Compatible | Sublimation dye cannot bond to cotton fibers |

| Wood | ✔ Conditionallly Compatible | Must be polymer-coated |

| Glass | ✔ Conditionallly Compatible | Must have sublimation coating |

| Leather | ✔ Conditionallly Compatible | Only coated synthetic leather works |

The key rule is simple: sublimation only works on polyester or polymer-coated surfaces.

Benefits of Using a Sublimation Printer

Sublimation printers offer significant benefits that make them ideal for personalized products, small businesses, and industrial production.

1. Vibrant, High-Resolution Prints

Sublimation printing produces images with smooth gradients, rich colors, and crisp details.

2. Long-Lasting Durability

The prints become part of the material’s structure, preventing peeling or cracking.

3. Wide Range of Printable Items

Users can print on mugs, fabrics, keychains, plates, puzzles, metal sheets, and more.

4. Cost-Effective for Small Businesses

Sublimation printing has low running costs and fast output speeds.

5. No Weeding Required

Unlike vinyl printing, sublimation does not require cutting or weeding excess material.

6. Eco-Friendly Printing

Sublimation uses dye instead of plastic-based inks, reducing waste.

Common Applications of Sublimation Printing

Sublimation printers are used widely across industries due to their versatility.

1. Fashion and Apparel Industry

Sublimation is ideal for all-over T-shirt printing, sportswear, leggings, and fashion accessories.

2. Personalized Gifts

Mugs, pillows, phone cases, and custom items are popular sublimation products.

3. Promotional Items

Businesses use sublimation for branded merchandise including keychains, lanyards, mousepads, and badges.

4. Interior Decorations

Photo panels, wall art, and custom tiles can be produced through sublimation.

5. Corporate Branding

Sublimation helps create employee uniforms, accessories, and office decor.

Limitations of Sublimation Printing

Although sublimation printing has numerous advantages, it also carries some limitations users should consider.

- Works only on polyester or polymer-coated surfaces

- Requires light-colored materials for best results

- Cannot be used on 100% cotton clothing

- Heat press equipment adds to setup cost

- Large-format printers require considerable space

- Colors may appear dull on sublimation paper before heating

Understanding these limitations helps individuals and businesses plan more effectively.

Maintenance of Sublimation Printers

Proper maintenance ensures longevity and consistent print quality.

Maintenance Tips

- Print test pages regularly to avoid clogged nozzles.

- Store sublimation ink in a cool and dry environment.

- Keep the printer dust-free to prevent contamination.

- Avoid long periods of inactivity to prevent ink drying.

- Use genuine ink and recommended papers for best results.

- Perform nozzle checks and cleaning cycles routinely.

Comparison: Sublimation Printer vs Other Printing Methods

Table 3: Comparison of Printing Methods

| Feature | Sublimation Printing | Inkjet Printing | Laser Printing | DTG Printing |

|---|---|---|---|---|

| Durability | Very high | Moderate | High | Moderate |

| Fabric Compatibility | Polyester-only | Most fabrics | Paper only | Cotton |

| Print Vividness | Excellent | Good | Limited | Excellent |

| Setup Cost | Moderate | Low | High | High |

| Suitable For | Personalized products | Home printing | Office work | Apparel |

How to Choose the Right Sublimation Printer

When selecting a sublimation printer, consider:

- Print size and format needed

- Intended volume of printing

- Ink tank size and cost

- Printhead reliability

- Availability of replaceable components

- Compatibility with sublimation inks

- Support and warranty

Matching the printer to your business or personal needs ensures long-term satisfaction and efficiency.

FAQs

1. What is a sublimation printer?

A sublimation printer uses dye that turns into gas under heat to create durable, vibrant prints on polyester or coated items.

2. What materials can I print on with sublimation?

Sublimation works best on polyester fabrics and polymer-coated items like mugs, metal panels, and tiles.

3. Do sublimation prints fade over time?

Sublimation prints are highly durable and resist fading, cracking, or peeling because they become part of the material.

4. Can I use sublimation on cotton?

No, sublimation dye cannot bond to cotton fibers, but cotton can be sublimated with special polymer coatings.

5. Is sublimation printing good for small businesses?

Yes, sublimation is cost-effective, easy to start, and ideal for personalized product businesses.